LIQTRA’s 3D Printing Ecosystem

The USP of LIQTRA’s technology is the combination of advanced hardware with proprietary software. As a result, our technology offers full control of every aspect of the 3D printing process, which can be optimized for a specific applicaiton.

Revolutionizing 3D Printing with Multi-Nozzle Technology

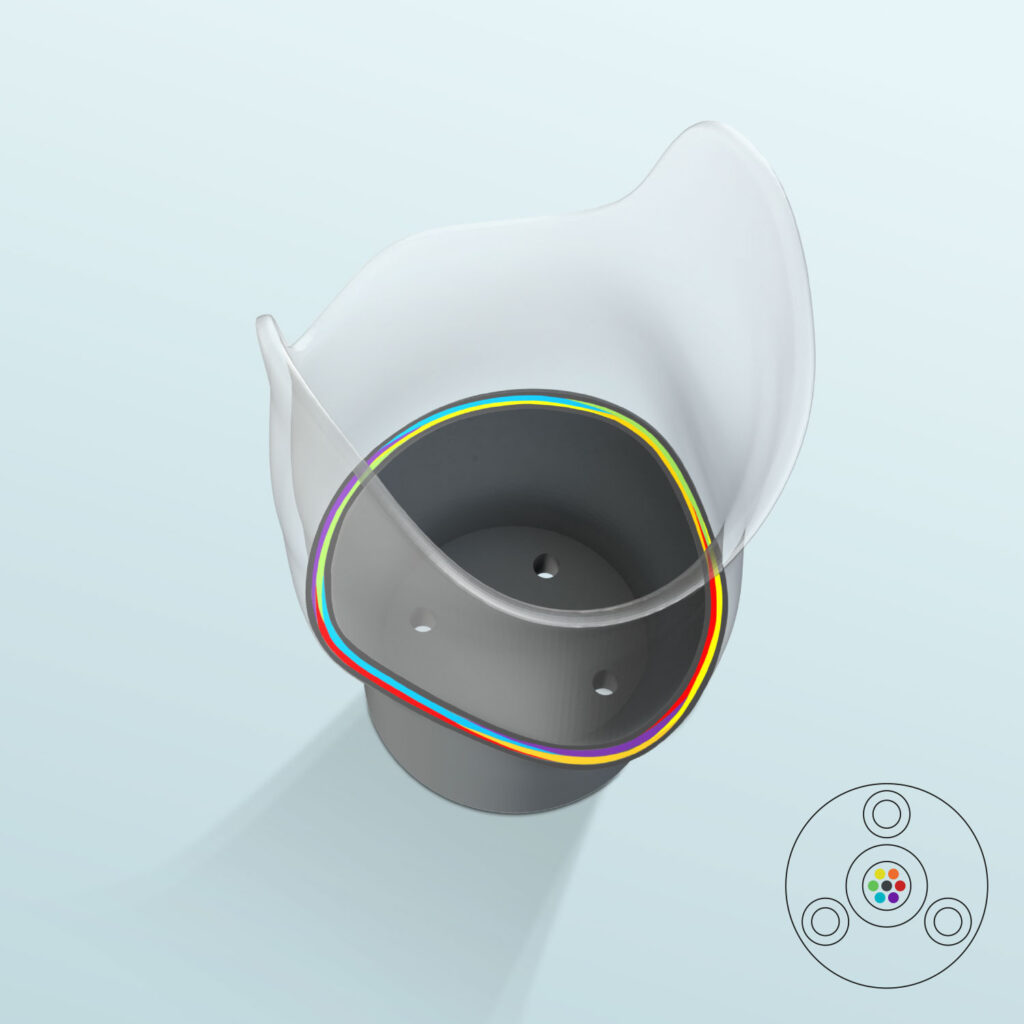

Variable Parallel ExtrusionThe patented multi-nozzle technology enables the simultaneous use of multiple nozzles in 3D printing, even when manufacturing complex parts. While conventional print heads only use the material output of a single nozzle, LIQTRA’s patented technology enables the simultaneous use of multiple nozzles. Unlike 3D printing with single nozzle technology (FFF/FDM), the multiplied material discharge does not compromise in production accuracy even with larger nozzle diameters or thicker print layers. Despite the extreme increase in material output, corner radii and layer thickness stay unchanged in multi-nozzle technology.

What makes our Multi-Nozzle Technology special

Our Technology USPMulti-Material 3D Printing

Using multi-material 3D printing offers new sustainable solutions. The use of recycled materials can be limited to the inside of the part. The outer surface of the part is still produced out of virgin material, meeting the given design requirements. This drastically reduces the amount of virgin material without sacrificing surface quality or color selection.

Higher Strength

Simultaneous Material Extrusion from multiple nozzles not only leads to faster 3D printing, but it also introduces heat more concentrated into the previously printed layers. At higher temperatures the bond with the newly printed material gets stronger. With nearly isotropic strength, 3D printing with LIQTRA’s multi-nozzle technology meets up to strength standards of traditional manufacturing processes.

Short Process Times

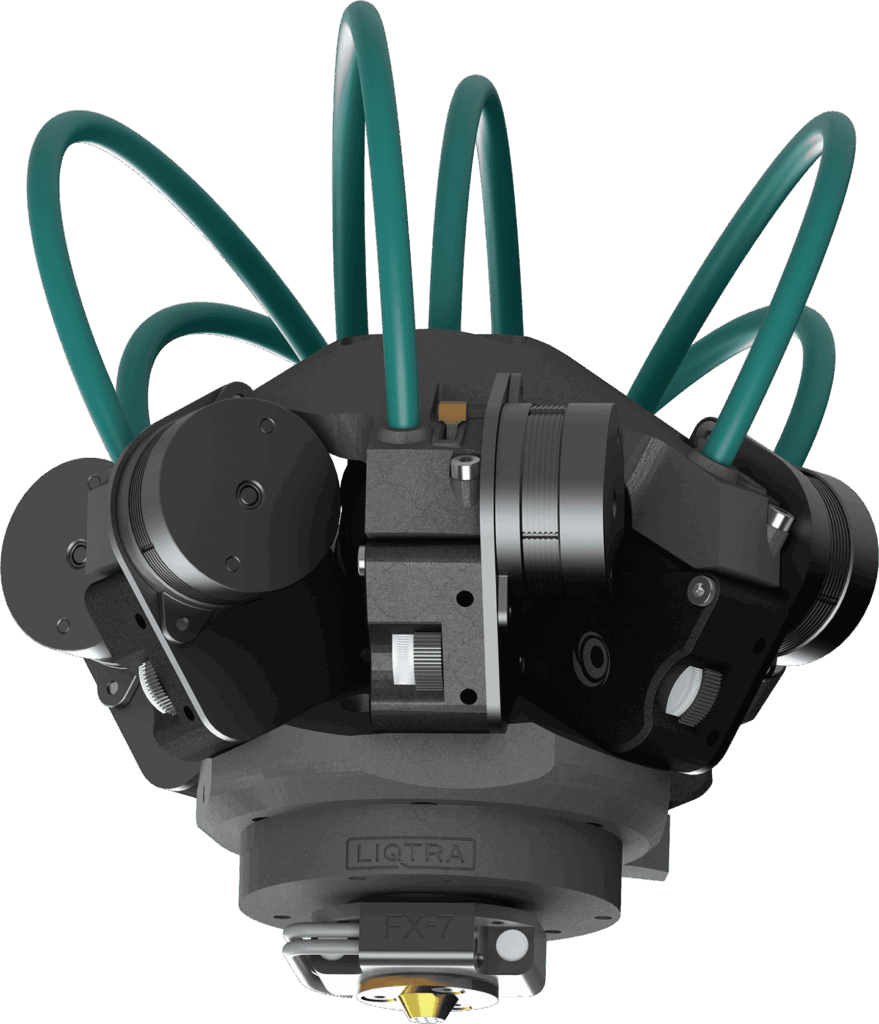

LIQTRA’s print head FX-7 enables process time reduction of up to 75 % due to individual nozzle control. The constant use of a central nozzle for producing the outer contour path ensures high part quality, while the surrounding nozzles print the inner contour paths simultaneously. The drastic reduction in process time enables new applications that were previously not possible with single nozzle technology.

Short Process Times with High Quality

Especially for fast 3D printing of parts with closed contours, LIQTRA has developed the print head FX-7. This print head utilizes up to seven nozzles that operate simultaneously, reducing process times by up to 75 %. The drastic reduction in process time enables new applications that were previously not possible with single nozzle technology.

Unlocking the Next Generation of 3D Printing

- +0%Productivity

- +0%

Strength

- -0%

Energy consumption

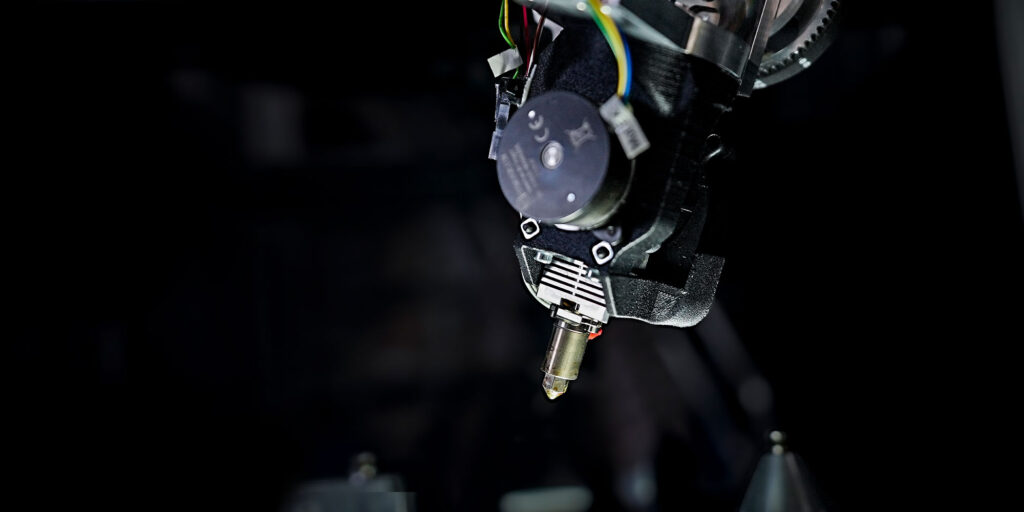

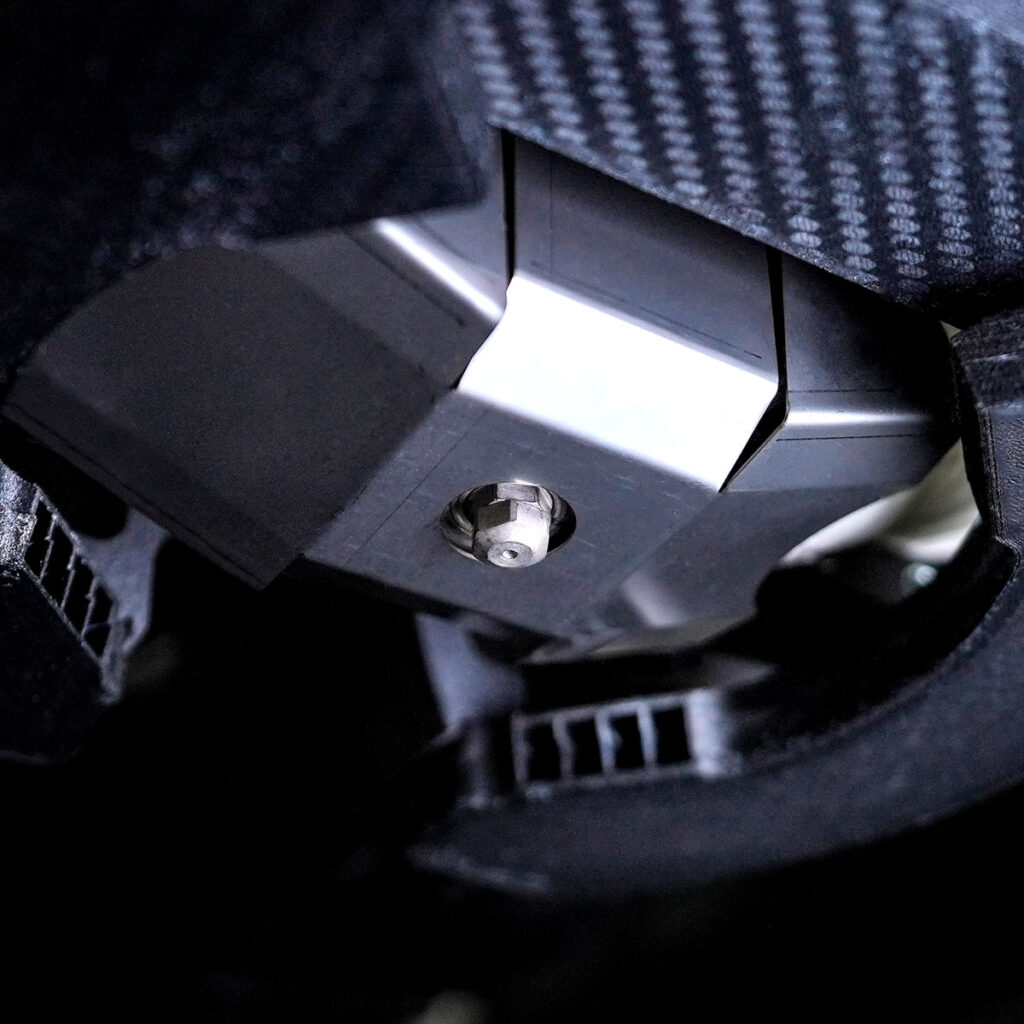

Valve Nozzle Technology Enables Precise and Dynamic Material Extrusion

The patented valve nozzle technology enables new degrees of freedom in part design and aims to bring FGF closer to the flexibility of Fused Filament Fabrication (FFF). Currently, many pellet-based 3D printers are only used in vase mode at constant discharge rates and without start/stop of the material extrusion. In addition to the limitations in component design, deviations in the printing process have a significant impact on component quality, for example in the case of deviating printing speeds. The combination of a metering pump and valve nozzle not only enables precise start and stop of material extrusion but also allows dynamic adjustment of the discharge rate during the printing process.

What makes our Valve Nozzle Technology special

Our Technology USPPrecise Material Extrusion

The valve nozzle technology enables the material discharge to be stopped at the end of the printed path by lifting the nozzle. The valve function prevents any pressure surge in the polymer melt in the nozzle, enabling the next path to be started precisely when the nozzle is opened again.

Dynamic Material Discharge

The material discharge can be dynamically controlled by the metering pump that is placed directly in front of the nozzle. The metering pump does not melt the material anymore, but feeds the polymer melt in defined volumes and can dynamically adjust the discharge.

Short Process Times

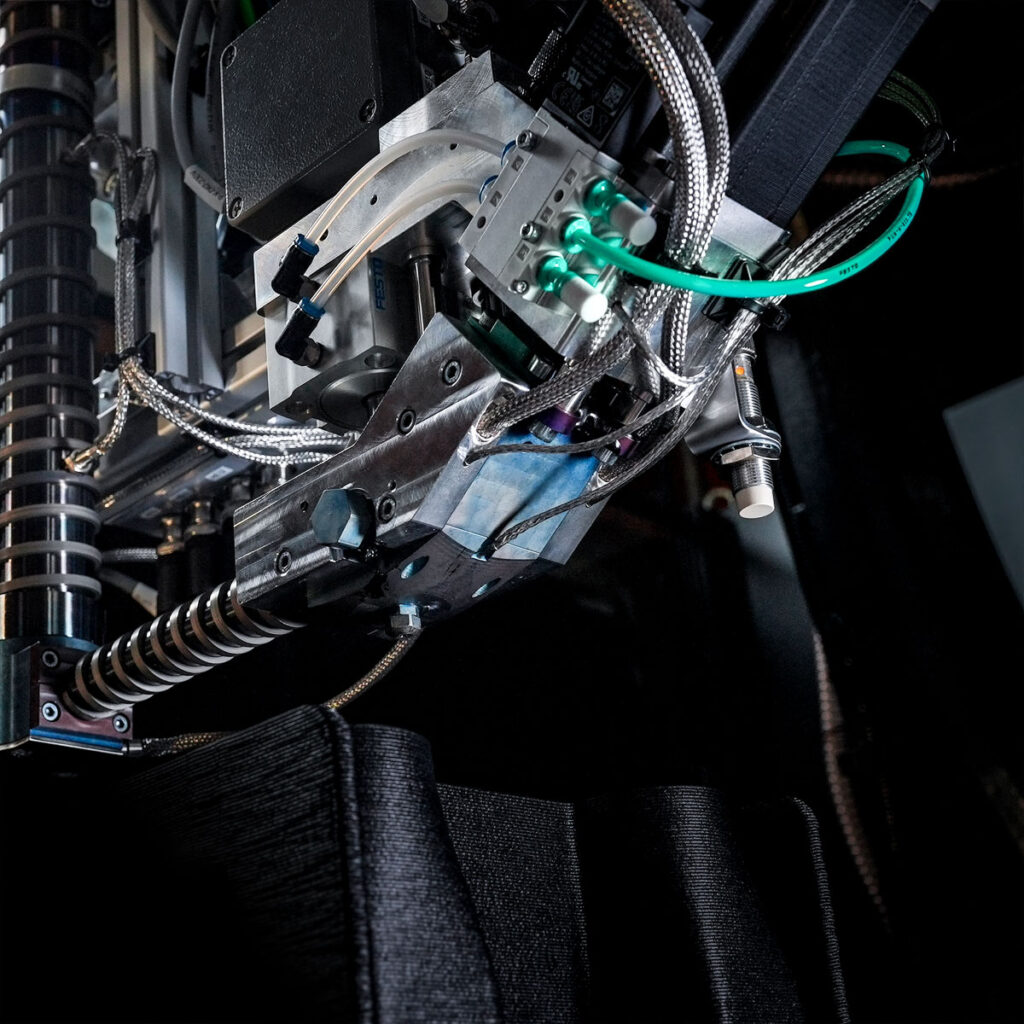

Separating the plasticizing unit and print head significantly reduces the moving mass compared to conventional technologies. Therefore, the lightweight print head can be positioned precisely at high printing speeds with high acceleration via linear direct drives using precision absolute encoders.

Redefining 3D Printing Performance

The LIQTRA print head VPX-1 is designed for high throughputs of fiber-reinforced pellets and the requirements of customer applications. The print head can easily be adapted to other boundary conditions with respect to nozzle diameter and material discharge. The nozzle diameter can be adjusted for individual applications, although the standard diameter is 2 mm.

Print Head VPX-1PX-Series

High-Speed 3D Printing Maximizes Productivity

- >0g/hThroughput

- >0mm/s

Printing Speed

- >0g

Acceleration

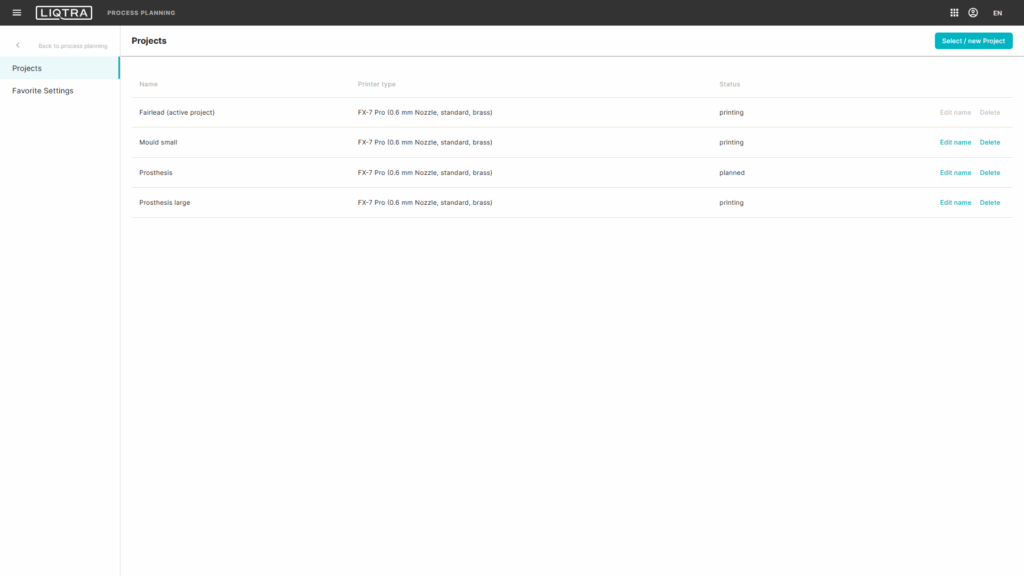

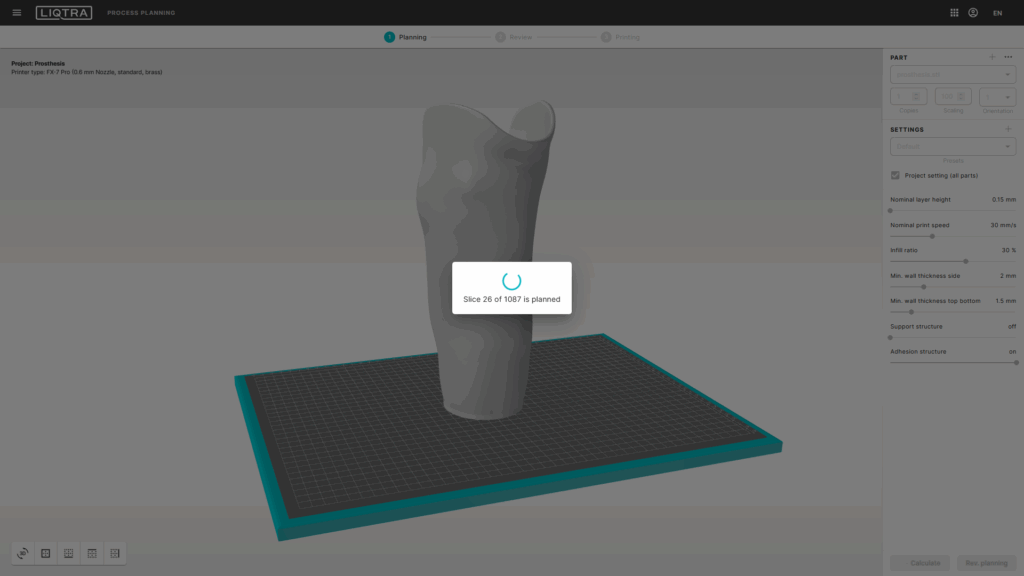

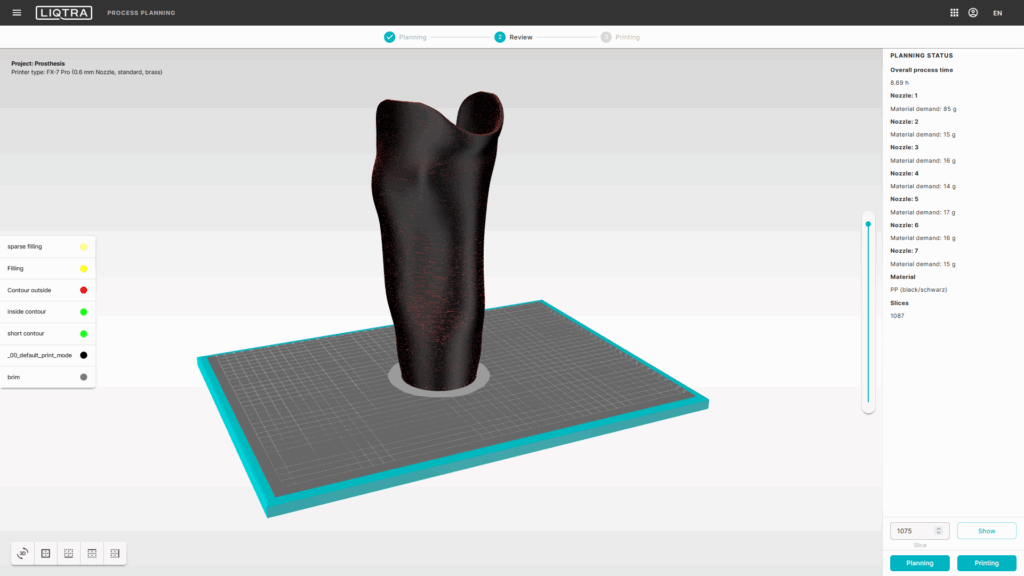

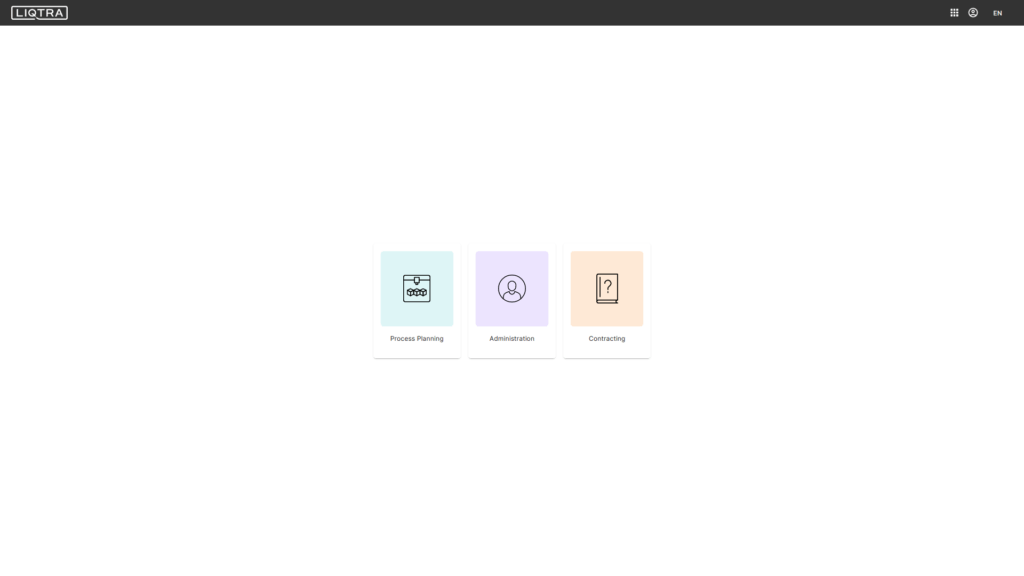

3D Printing Software Meets Production Management

The digital platform offers users to centrally manage data, projects and print jobs. The slicing software enables convenient and intuitive process planning. Print jobs can be planned in the browser with integrated communication to our 3D printers. With just a few clicks and no prior 3D printing knowledge, the user can arrive at an optimized print job. Print jobs can be started directly on the 3D printer on site or forwarded to LIQTRA’s 3D printing service.

Customer CenterServer-based software

No installation on the client computer is required due to the use of web technologies. The software is automatically available in the latest version.

Simplified operation

Proven process profiles significantly reduce the number of necessary manual adjust-ments of the process parameters.

Printer connection

Print jobs are sent from the planning interface directly to the 3D printers and the progress is monitored during printing.

Print job management

All print jobs are stored in customers profiles and can be printed again at any time. Proofen quality is available for the next production lot.