Empower Your Business With Custom Additive Solutions

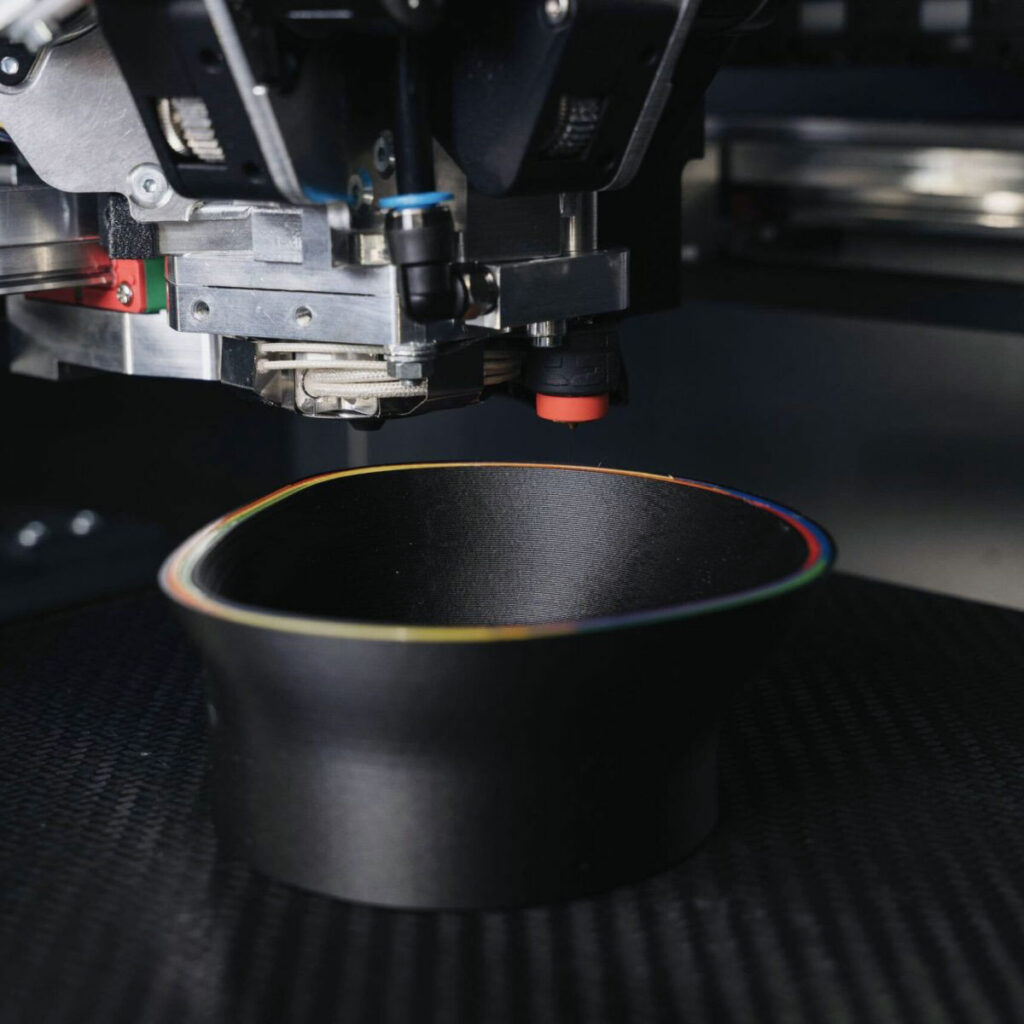

Innovation at Every LayerFor the economical use of 3D printing in an industrial environment, LIQTRA offers custom breakthrough hardware and software solutions. Suitable and resource-efficient 3D printing solutions for individual applications enable economical and reliable manufacturing processes – from individual parts to small series production.

LIQTRA is 3D Printing Success for Stakeholders Across Industries

LIQTRA provides innovative solutions tailored to a wide range of business needs. Our technology empowers companies to enhance efficiency, drive sustainability, and adapt to changing market demands. Explore our success stories to see how LIQTRA’s solutions are applied across various sectors, delivering real-world impact and measurable results.

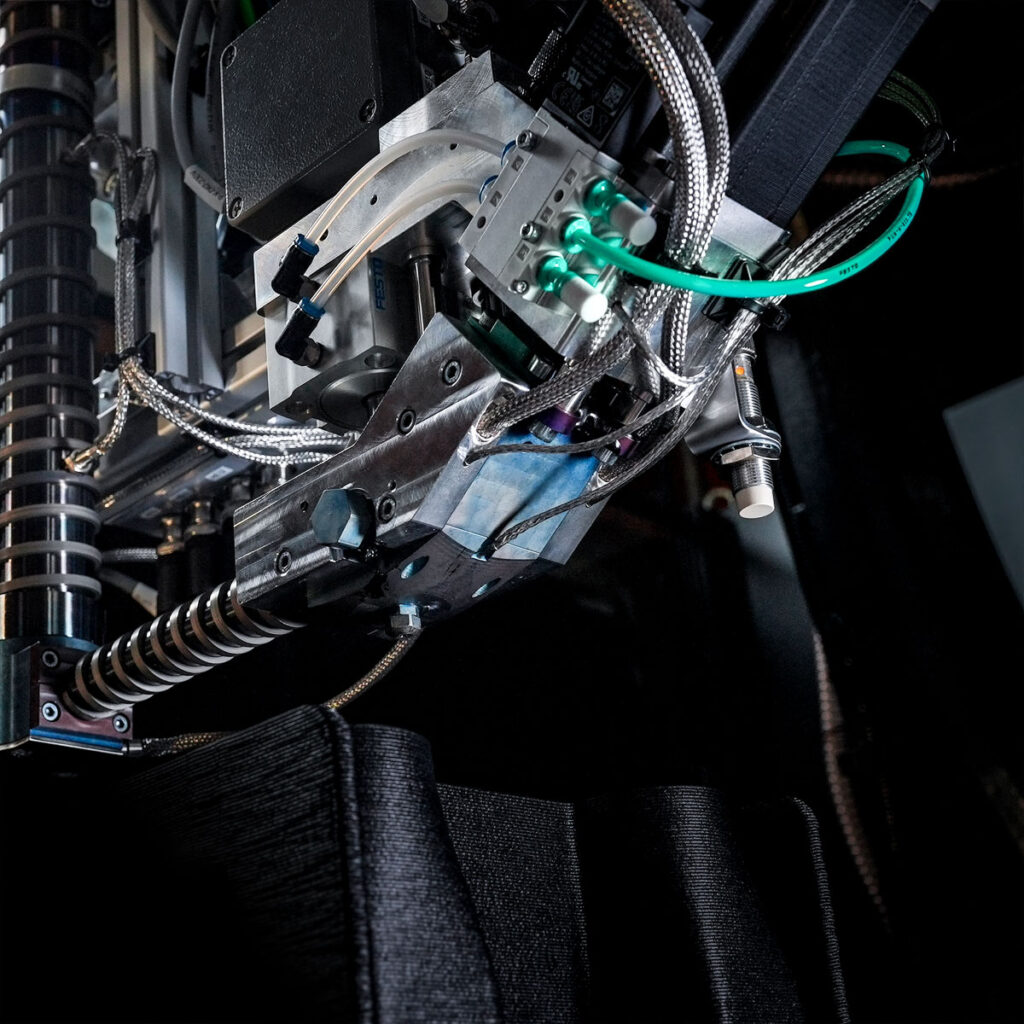

Redefining 3D Printing Performance

Valve nozzle technology enables precise and dynamic material discharge, allowing new applications to be implemented for Fused Granular Fabrication (FGF).

High Productivity

Precise Material Extrusion

Dynamic Material Discharge

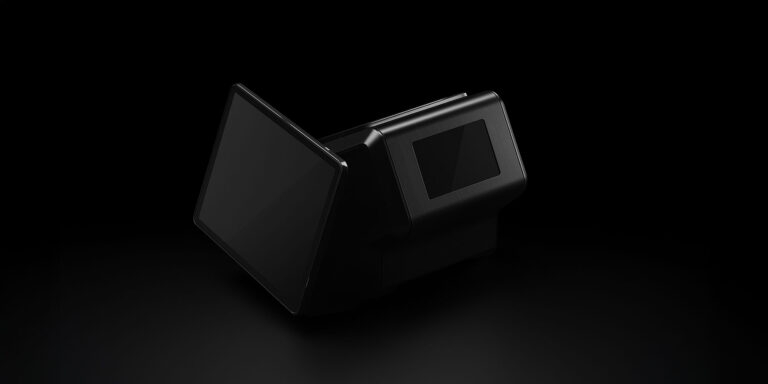

Multi-Nozzle Technology Unlocks New Potentials

The combination of multiple nozzles for a single print job enables shorter production times and new applications in Fused Filament Fabrication (FFF), such as multi-material 3D printing.

High Productivity

Higher strength

Multi-Material 3D Printing

Entering Industrial 3D Printing with LIQTRA

The unique team with 40+ years of experience in AM developing cutting-edge hardware and software solutions supports its customers along the entire value chain with four essential service areas.

ServicesProduct Development

From the design of electronic components to the construction of complex parts – LIQTRA offers holistic product development.

Product Design

The potential of Additive Manufacturing is exploited by part design – let LIQTRA help to create optimized part designs for 3D printing.

Production

LIQTRA’s machine park offers large capacities for industrial manufacturing in 3D printing – from individual parts to series production.

Consulting

The overall package of part design, material and machine is key for the successful use of 3D printing – let LIQTRA assist you.

40+ Years of Experience in AM Developing Cutting-Edge Hardware & Software Solutions

LIQTRA aims to establish itself as a leading provider of 3D printing technologies, as well as a pioneer in Additive Manufacturing processing recycled polymer filaments and pellets. To tackle the major problems of the future, the highly skilled and experienced problem-solving team develops breakthrough hardware and software solutions for next-generation 3D printing technology. If you would like to join us on this journey, become part of the team.